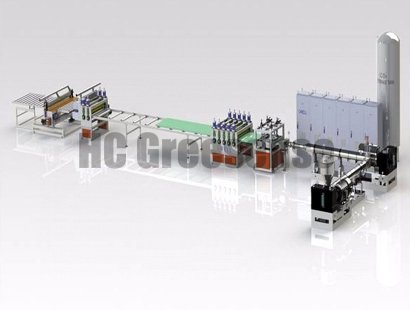

It is a new product launched by our company. The equipment has a fast board, low scrap rate, large output, low bulk density and long service life. The model is complete and the operation is mature. The output and thickness of the same model are higher than the same industry level, especially the large output and thickness models meet the needs of large and high-end customers at home and abroad.

-

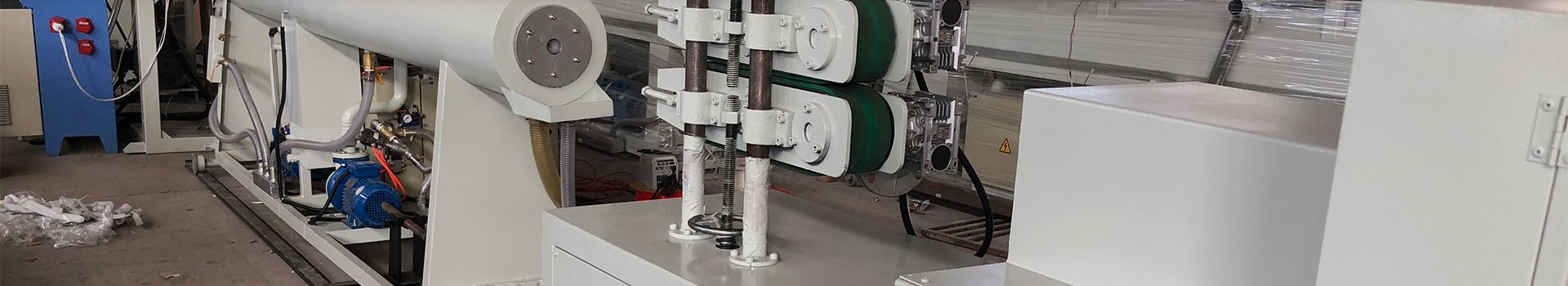

Plastic Pipe Extrusion Line

- 3PE Steel Pipe Anti-corrosion equipment

- Solid Thick Wall Spiral Pipe Machine

- PE Pipe Machine

- PPR Pipe Machine

- PVC Pipe Machine

- Insulation Pipe Machine

- Spiral type Corrugated Pipe Machine

- Spiral PU Insulation Jacket Production Machine

- Single Wall Corrugated Pipe Machine

- Two step PU Insulation Production Line

- Steel Wire Reinforced Pipe Machine

- Krah Machine

- Rib Reinforced Spiral Pipe Machine

- Double Wall Corrugated Pipe Machine

- Double Wall Corrugated Pipe Cladding Machine

- Double Plastic Compounded Pipe Machine

- Steel Reinforced Spiral Pipe Machine

- Carbon Fiber(COD) Spiral Pipe Machine

- Fresh Air Transport DWC Pipe Machine

- One Step Insuatlion Pipe Machine

- Hollow Wall Winding Pipe Machine

- Plastic Board Extrusion Line

- Recycling Crushing, Pelletizing Line

- Plastic Profile Extrusion Line

一级标题

一级标题