The PVC hot-cutting granulation production line mainly adopts the hot-cutting method to dry-grain the plastics with relatively cold-solid properties (such as HDPE, PVC) and filled modified plastics (such as calcium-filled). This production line has the advantages of high pelletizing precision and high heat cutting yield. The die face hot cutting granulation makes the material particles smooth and full and beautiful. Because the system adopts the modular design, the user can also select the secondary air supply, vibrating screen and other configurations according to the process requirements to achieve different process requirements.

-

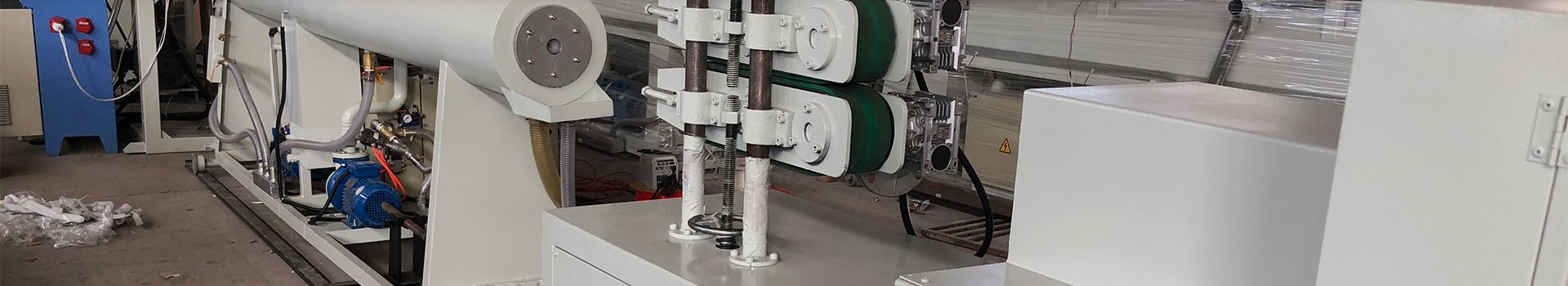

Plastic Pipe Extrusion Line

- 3PE Steel Pipe Anti-corrosion equipment

- Solid Thick Wall Spiral Pipe Machine

- PE Pipe Machine

- PPR Pipe Machine

- PVC Pipe Machine

- Insulation Pipe Machine

- Spiral type Corrugated Pipe Machine

- Spiral PU Insulation Jacket Production Machine

- Single Wall Corrugated Pipe Machine

- Two step PU Insulation Production Line

- Steel Wire Reinforced Pipe Machine

- Krah Machine

- Rib Reinforced Spiral Pipe Machine

- Double Wall Corrugated Pipe Machine

- Double Wall Corrugated Pipe Cladding Machine

- Double Plastic Compounded Pipe Machine

- Steel Reinforced Spiral Pipe Machine

- Carbon Fiber(COD) Spiral Pipe Machine

- Fresh Air Transport DWC Pipe Machine

- One Step Insuatlion Pipe Machine

- Hollow Wall Winding Pipe Machine

- Plastic Board Extrusion Line

- Recycling Crushing, Pelletizing Line

- Plastic Profile Extrusion Line

一级标题

一级标题