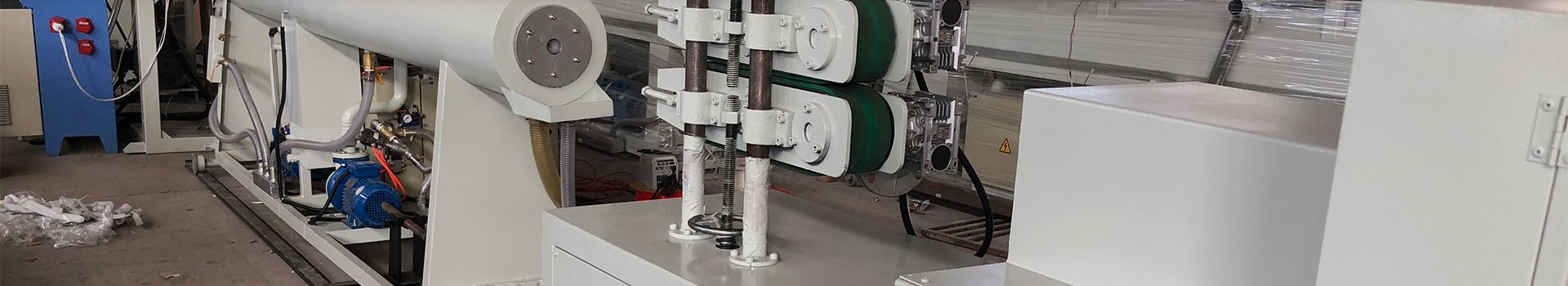

The production line of PE and PP gas water supply pipes produced by HC Greesence Plastic Machinery Co., Ltd. is mainly used for the production of agricultural water supply and drainage, building water supply and drainage, cable laying and so on. The unit consists of a vacuum qualitative table, a tractor, a cutting machine, and a turning rack.

-

Plastic Pipe Extrusion Line

- 3PE Steel Pipe Anti-corrosion equipment

- Solid Thick Wall Spiral Pipe Machine

- PE Pipe Machine

- PPR Pipe Machine

- PVC Pipe Machine

- Insulation Pipe Machine

- Spiral type Corrugated Pipe Machine

- Spiral PU Insulation Jacket Production Machine

- Single Wall Corrugated Pipe Machine

- Two step PU Insulation Production Line

- Steel Wire Reinforced Pipe Machine

- Krah Machine

- Rib Reinforced Spiral Pipe Machine

- Double Wall Corrugated Pipe Machine

- Double Wall Corrugated Pipe Cladding Machine

- Double Plastic Compounded Pipe Machine

- Steel Reinforced Spiral Pipe Machine

- Carbon Fiber(COD) Spiral Pipe Machine

- Fresh Air Transport DWC Pipe Machine

- One Step Insuatlion Pipe Machine

- Hollow Wall Winding Pipe Machine

- Plastic Board Extrusion Line

- Recycling Crushing, Pelletizing Line

- Plastic Profile Extrusion Line

一级标题

一级标题